uci hardness tester principle|ultrasonic contact impedance hardness tester : manufacturers “Ultrasonic Contact Impedance” is based on a 136 degree diamond at the end of a vibrating rod being depressed into the test surface at a fixed load. The difference in Ultrasonic vibration frequency is then calculated into a hardness value. The UCI hardness test procedure is slower than the Dynamic Impact style, however the “UCI” method of hardness testing is portable, .

Leu todo o conteúdo disponibilizado e se interessou ainda mais pelo livro? Compre-o e incentive o autorclicando no link a seguir: Ver mais

{plog:ftitle_list}

Resultado da You'll find bags, belts, watches, shoes, sunglasses, clothes and more. Whether you're browsing for yourself or shopping for someone special, you're sure to find something to love in our sale collection. Also explore our Black Friday & Cyber Monday Sales to get deal bags, wallets and more.

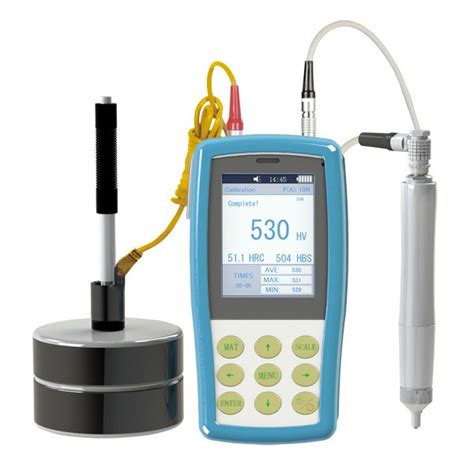

ultrasonic hardness tester

The UCI method (Ultrasonic Contact Impedance or modified Vickers procedure) – first put to use in 1965 under the name “SonoDur” - electronically evaluates each Vickers hardness test indentation in a fraction of a second and . The UCI (Ultrasonic Contact Impedance) method can be used to measure the hardness on a wide field of applications. In this Video we explain the UCI Technolog.

homebrew refractometer reviews

Hardness testing using the MIC 20 in combination with the test support MIC 227 and a UCI probe in the heat-affected zone (HAZ) of a weld. Fig. 2: Hardness testing with a rebound hardness tester (DynaMIC) on the drive wheel of a large hydraulic excavator. Fig. 3: Hardness testing using the DynaPOCKET on the chain of an open-pit mining excavator . UCI hardness tester is made with a hand-held probe and host connected by a cable. The probe has a vibration bar a 136-degree diamond at the end or also known as a Vickers. the vibration bar creates the ultrasonic .Principle of portable hardness testing by Phase II+ Why portable hardness testing? Portable hardness testers have come of age since the late 90’s, with a vast offering of high . UCI test procedure is slower than the Dynamic Impact style, however the “UCI” method of hardness testing is portable, easy and accurate. It also has its own .

“Ultrasonic Contact Impedance” is based on a 136 degree diamond at the end of a vibrating rod being depressed into the test surface at a fixed load. The difference in Ultrasonic vibration frequency is then calculated into a hardness value. The UCI hardness test procedure is slower than the Dynamic Impact style, however the “UCI” method of hardness testing is portable, . The UCI (Ultrasonic Contact Impedance) method is a portable and versatile modern technique for testing hardness. It operates on the premise that the frequency of an oscillating rod changes when it penetrates a sample. The UCI technique is ideal for fine-grained materials, narrow components, and components with hardened surfaces. Understanding How .

4.1 The hardness of a material is a defined quantity having many scales and being dependent on the way the test is performed. In order to avoid the creation of a new method involving a new hardness scale, the UCI method converts into common hardness values, for example, HV, HRC, etc.The UH200 non-destructive ultrasonic hardness tester, relying on the principle of ultrasonic vibration sensor rod, can easily and swiftly detect the material hardness of several metals without any damage. . Measurements of hardness can be made using the UCI hardness test in places that are challenging to reach, including the sides of teeth or .Barcol hardness testers are very portable, and are good for this type of comparative work, but the conversion to more widely recognised hardness scales is only approximate. . The principle of UCI is based on the shift in resonant ultrasonic frequency arising from the contact of a Vickers diamond indenter on the end of the probe, and the .

The UCI Hardness Tester TCM-U3 operates according to the Ultrasonic Contact Impedance (UCI) method of hardness testing, and is standardized according to ASTM A 1038. The basic operating principle is that hardness is measured by detecting the frequency shift of a longitudinal oscillating rod fused to a Vickers diamond indenter.The NOVOTEST Lab UCI wireless hardness tester implements the ultrasonic contact impedance method. The users of NOVOTEST Lab UCI get the following advantages:. Ultra-portable device for quick hardness testing anywhere – in laboratories or in field conditions, with autonomous continuous operation up to 20 hours.Rockwell, UCI, and Leeb hardness measurements are widely used in quality control across a variety of industries. A common factor among these applications is the need to test large, bulky metallic materials (often converted to the Rockwell HRC .The MIC 10 Portable Hardness Tester. Quick and versatile hardness testing using the UCI principle. Features: Easy to handle - weighs less than 11 oz . Operation based on the UCI Principle; Tests in any direction; Selection of interchangeable probes are available having loads from .1 to 10 kgf, to vary the indentation size from one that cannot .

The UCI Hardness Tester TCM-U2 operates according to the Ultrasonic Contact Impedance (UCI) method of hardness testing, and is standardized according to ASTM A1038 . The basic operating principle is that hardness is measured by detecting the frequency shift of a longitudinal oscillating rod fused to a Vickers diamond indenter. Even though the UCI test procedure is slower than the dynamic impact method, it is portable, easy and accurate. UCI testers are not restricted to large mass and these units can test metals as thin as 1 millimeter and at a hardness value as low as 20 HRC (75 HB). They also can perform hardness tests on larger, harder metals, as well.The All-In-One Portable Hardness Testing Solution (Page 5) (Page 7) (Page 9) Ease of Use • Large touchscreen • Personalized views • Custom reports Powerful Hardware . Equotip® 550 UCI The UCI Measuring Principle The UCI (Ultrasonic Contact Impedance) method uses the same pyramid-shaped diamond as a conventional VickersProceq's Equotip enables portable hardness inspection of almost any object, polished parts and heat-treated surfaces. The hardness measurements are made by using the dynamic rebound testing method according to Leeb, the .

Universal Hardness Tester . UCI 3000 . Instructions Manual . Thank you for your purchase of this product. This manual describes how to use your UCI 3000 Universal Hardness Tester. Be sure that you have read and understood its contents before using . with ultrasonic contact impedance principle. To avoid any unnecessary damage and loss,The UH200 non-destructive ultrasonic hardness tester, relying on the principle of ultrasonic vibration sensor rod, can easily and swiftly detect the material . UCI Method for Hardness Testing: The UCI hardness measuring method complies to ASTM A1038. The ultrasonic contact impedance (UCI) probe is purposed to be .hardness test indenter is going to influence the hardness measurement and will thus lead to remarkable . hardness according to the Rockwell principle while using a lower load of 50 N. . UCI Hardness . UCI.

Since Proceq invented the Leeb hardness test principle in 1975, Equotip has become established as a globally recognized brand for portable hardness testing and a de facto industry standard. . Equotip UCI Test Block Additional Calibration HB, ISO 6506-3, one side: Add to cart: 357 90 941: Equotip UCI Test Block Additional Calibration HR, ISO .The UCI Measuring Principle. The UCI (Ultrasonic Contact Impedance) method uses the same pyramid-shaped diamond as a conventional Vickers hardness tester. Unlike Vickers testing, no optical evaluation of the indentation is required, enabling fast and portable measurements. The UCI method excites a rod into an ultrasonic oscillation.PCE-5000 is a portable hardness tester that uses the ASTM A1038 ultrasonic contact impedance (UCI) method to measure the hardness of metals and alloys with a minimum thickness of 2 mm / .08 in. Ultrasonic hardness testing is considered nondestructive, as it creates a microscopic indentation only visible when using a high-powered microscope.There are two different physical methods which are particularly recognized in the practical field: the static Ultrasonic Contact Impedance (UCI) method and dynamic rebound hardness testing (Leeb). The decision as to which method is to be used mainly depends on the testing task.

2 UCI/Dynamic Hardness Tester PHT-6000 Series “Ultrasonic Contact Impedance . “Dynamic Impact” is based on the Leeb principle of hardness,developed by Dietmar Leeb in the 1970’s. A spring loaded impact body is thrust to the test surface, effecting rebound. The speed of both the initial thrust and the rebound is measured in a non .The SonoDur 3 is the latest generation of portable UCI Hardness Tester from NewSonic. Featuring the Android Operating System, the SonoDur 3 has data transfer and export functions via USB, WLAN or Bluetooth with virtually unlimited storage capacity of measurement data. Replaces MIC10/MIC20 & Conforms to ASTM/DIN The SonoDur 3 (and SonoDur 2) replaces .The reliable hardness test probes with high precision and sustainable measured value stability for our manual measuring probes, motor probes and new mobile SONO-S stand; . Measuring principle: UCI Method, corresponds to DIN 50159, ASTM A1038. Test indenter:

ultrasonic contact impedance hardness tester

uci hardness testing method

homebrew refractometer stir

uci hardness test

There is a new draw every 3:30 minutes and each draw offers the chance to win $200,000. You can add Keno Bonus to your ticket and multiply your potential winnings by 1.5x, 2x, .

uci hardness tester principle|ultrasonic contact impedance hardness tester